Sai Tech Laser

Steel Sheet Material Laser Cutting, Bending, and Welding Flow Chart.

This flowchart represents the step-by-step process of fabricating steel sheet components using laser cutting, bending, and welding techniques.

Raw Material Preparation

- Selection of appropriate steel sheet (Mild Steel, Stainless Steel, etc.)

- Material thickness verification

- Cleaning and surface preparation

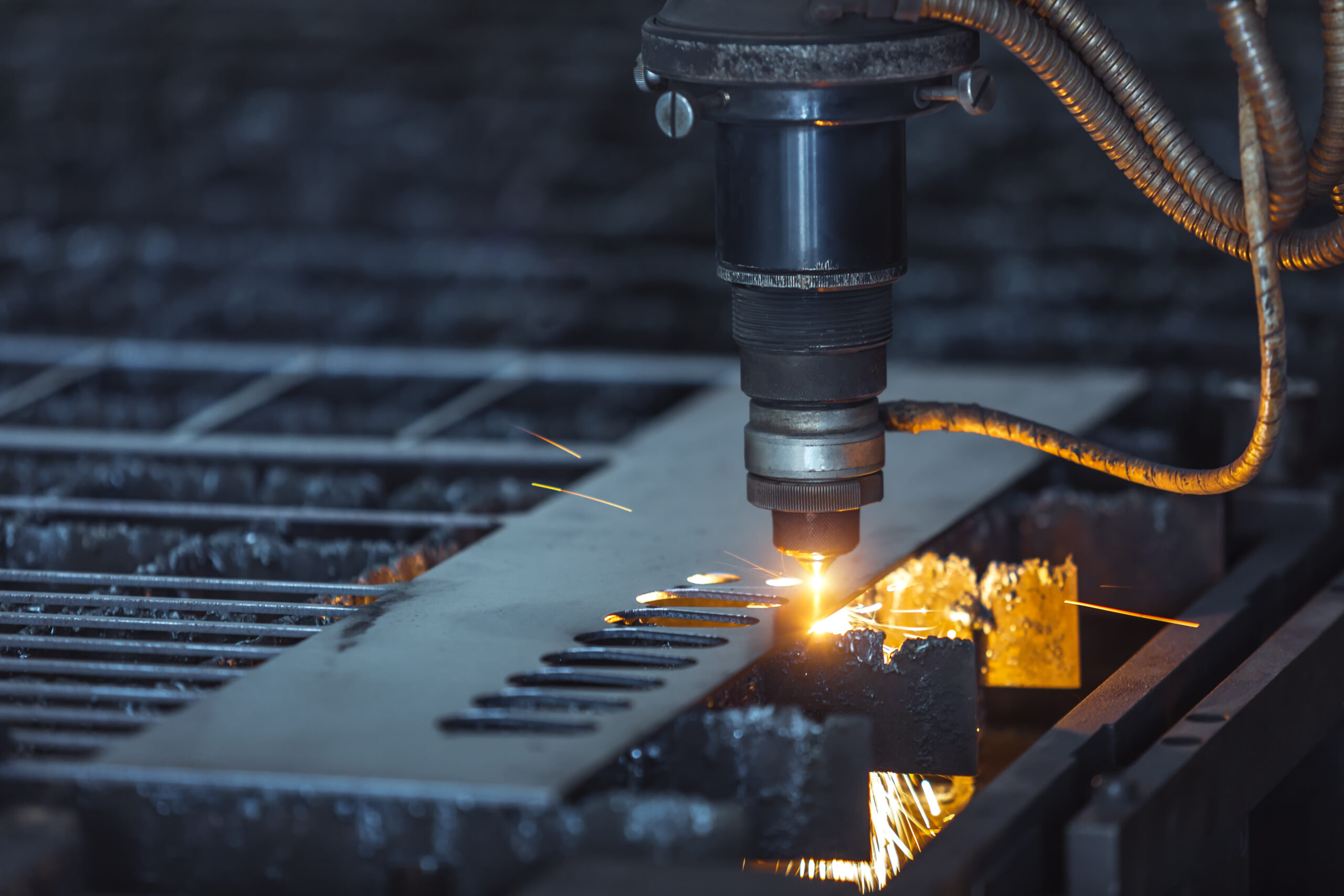

Laser Cutting Process

- Programming & Design

- Import CAD files into CNC laser cutting machine

- Set cutting parameters (power, speed, gas type)

- Cutting Execution

- Precision laser cutting as per the design

- Removal of dross and burrs

- Quality inspection of cut parts

Sheet Metal Bending (Press Brake Operation)

- Tooling Setup

- Selection of the correct bending die and punch

- Machine calibration

- Bending Process

- CNC press brake applies force for accurate bending angles

- Multi-stage bending (if required)

- Measurement and inspection of bends

Welding Process

- Edge Preparation

- Grinding and cleaning of edges for welding

- Alignment and clamping of parts

- Welding Execution

- Selection of welding method (MIG, TIG, Spot Welding, etc.)

- Controlled heat application to avoid warping

- Quality check for defects (cracks, porosity, misalignment)

- Post-Weld Treatment

- Grinding and smoothing weld joints

- Stress-relief treatment (if necessary)

Surface Finishing & Coating

- Deburring and polishing

- Surface cleaning (sandblasting, pickling)

- Powder coating, painting, or galvanization (if required)

Final Inspection & Quality Control

- Dimensional accuracy check

- Weld strength testing

- Visual and functional inspection

Packaging & Dispatch

- Protective packaging for transport

- Labeling and documentation

- Shipment to the customer or next stage in the production proces